FiBart Home is a textile company specialized in made in Italy furniture fabrics. It is actively engaged in research, design and production of high quality end products. The company is able to meet the strictest criteria of sofa manifactures and motorhomes combining quality and performances, with an attentive care to the needs of residential customers.

The constant research of new products allows the company to offer cutting-edge fabrics, developing new ideas, not only with respect to designs, but also by innovating yarns, weaving and finishing.

FiBart Home is located in the heart of Tuscany, a historic territory of textile tradition.

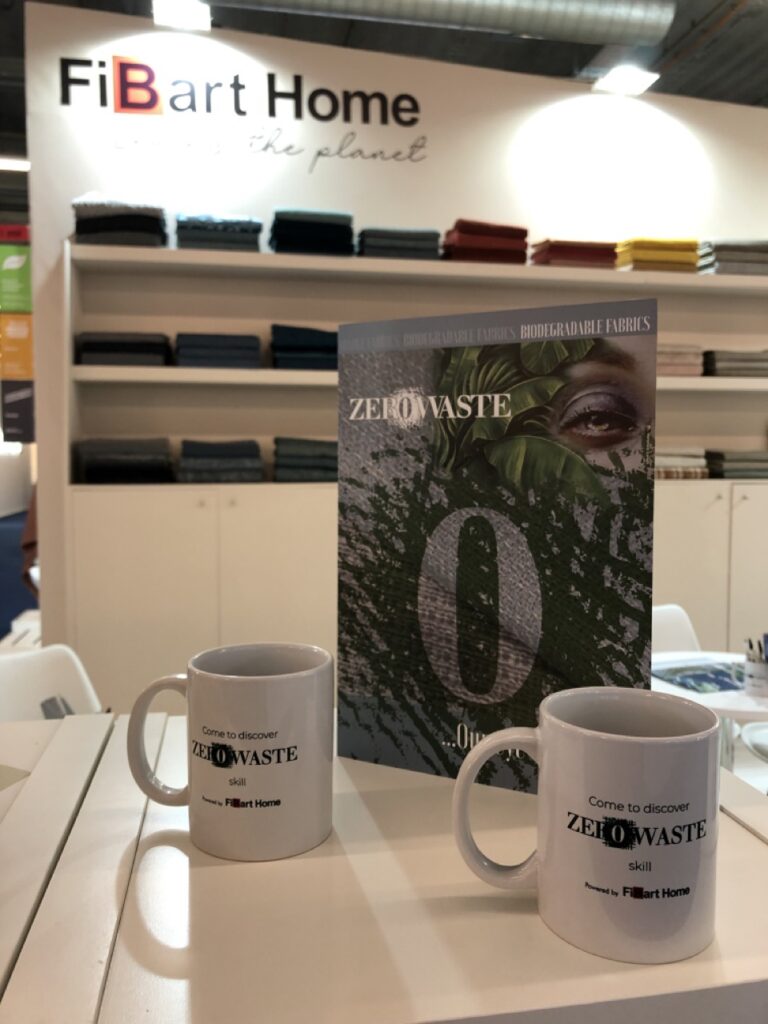

“Living the planet” is the slogan that identifies the path taken by the company in the production of recycled and biodegradable fabrics. The choice of FiBart Home as a young company is always oriented to the most sustainable solution, because it considers the planet as the home of all living beings and therefore intends to protect it in ever possible way.

FiBart Home has created ZeroWaste, an innovative, recycled and biodegradable fabric, whose durability and performance remains unchanged compared to any other polyester yarn, but with a decomposition time of 3 – 5 years estimated compared to 300 for a classic polyester. In fact, it is a yarn obtained from the recycling of plastic bottles, modified by a mixture of organic compounds that do not interfere with the properties of the final product or with the various phases of the production process.

FiBart Home fabrics comply with REACH (Registration, Evaluation, Authorization and restriction of Chemicals) regulations which exclude the use of chemical substances harmful to the environment and human health from production.

Furthermore, the raw materials used in the FiBart Home fabrics are certified:

The Global Recycle Standard is promoted by Textile Exchange, an international non-profit organization for responsible and sustainable development in the textile sector.

It provides for an environmental declaration verified by a third party, which ensures the recycled material content of their products, both intermediate and finished, the maintenance of traceability throughout the entire production process, the restrictions on the use of chemical products and the respect of environmental criteria and social aspects in all phases of the production chain from the recycling of materials, to the subsequent manufacturing phases, up to the labeling of the finished product.

Oeko-tex Standard 100 is a control and certification system for all types of textile products born in 1992 which verifies the absence of harmful substances in all products in direct contact with the skin. It indicates that the manufacturer is certified as environmentally friendly both in processes and factories, as well as tested to verify the absence of harmful substances. It stands for customer trust and high product safety

The UN Sustainable Development Goals, in addition of being a universal call to action, represent the map of values from which companies can take inspiration to build a corporate strategy aiming a sustainable innovation of their business.

FiBart Home has embarked on the path to support and alignment with the following SDGs

CLEAN WATER AND SANITATION: Ensure availability and sustainable management of water and sanitation for all. Recycled fabrics comply with the REACH (Registration, Evaluation, Authorization and restriction of Chemicals) regulation by excluding the use of harmful chemicals from production.

DECENT WORK AND ECONOMIC GROWTH:

RESPONSIBLE CONSUMPTION AND PRODUCTION:

Ensure sustainable models of production and consumption.

FiBart Home has chosen circularity as a concrete action to “live the Planet” (Living the Planet) as if it were the living room at home. 60% of FiBartHome production is of recycled fabrics from pre- and post-consumer recycled fiber. Fibart Home’s goal is to reach 70-80% in the next few years also thanks to the innovative Zero Waste.

LIFE ON LAND:

Protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, halt and reverse land degradation, and halt the loss of biological diversity.

The production chain distributed within a radius of 20 km reduces the CO2 produced by logistics for the handling of goods during the various production phases, with less impact on the environment. FiBart Home has adhered to the strict criteria of the Standard 100 by OECO-TEX® to create fabrics, that protect the health of people and the environment from the risks of harmful substances.

FibartHome company

has chosen Moebeus consultancy

To identify its own positioning and own sustainability performance indicators . It has also identified its circularity rating with an in-depth analysis of circular strategies and business models to enhance and improve its processes.

FiBart Home

Via Salcetana 92

51031 Agliana (PT), Italia

commerciale@fibarthome.it

+39 0574 1550455